heaterSteam Model UR

heaterSteam process completes the range of heater humidifiers, offering a modular and versatile solution. heaterSteam process is the ideal solution for applications in which reliability and operating flexibility are needed when feedwater characteristics not always under control or may vary over time, such as marine applications. In these cases, or even when the feedwater needs to be softened, immersed electrode humidification is usually problematic, if not impossible. In general, with heater technology, the quality of steam production can be affected by the generation of foam due to the use of softened water. Water that is very rich in minerals, on the other hand, increases maintenance requirements.

heaterSteam process, however, fears no type of water: the heaters used in heaterSteam process are made from Incoloy® 825, a highly resistant and versatile superalloy developed to work in variable feedwater conditions. Protection against overheating guarantees safety and reliability in all situations, while the thermal shock function periodically detaches any scale from the heaters, diminishing the frequency and complexity of maintenance operations. The versatility of heaterSteam process is also reflected in its modularity. The Main/Secondary “mirror” function in fact allows up to 19 units to be controlled in parallel using a proportional signal, thus extending the capacity of the humidification system to 4-3527 lb/h without any complications whatsoever.

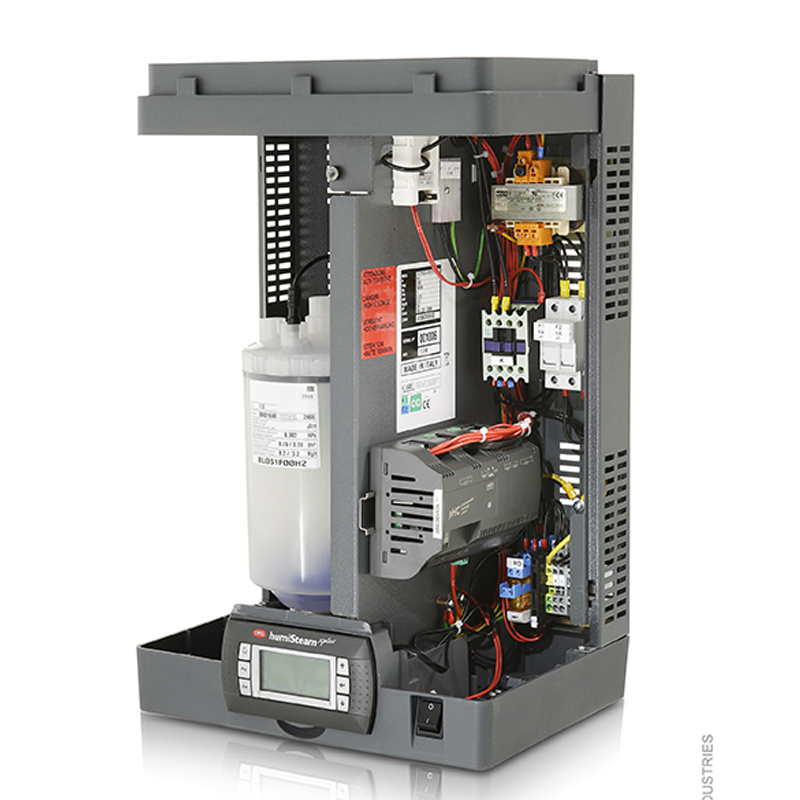

humiSteam Model UE

humiSteam basic (Y) is suitable for installation in civil environments, offices, hospitals and industrial facilities, and is designed for installation both in rooms, using the steam blower, and air ducts, using the linear steam distributors. humiSteam basic is ideal for applications where steam production is controlled by an external signal, i.e. BMS or humidistat, and comes in a range from 1.5 to 65 kg/h.

gaSteam Model UG

Steam humidifiers that exploit the heat value of gas, with the possibility of indoor and outdoor installation (IAS 12-94) for temperatures from -40 to 45°C.

Production ranges from 45 kg/h to 450 kg/h, using the latest generation CAREL controllers that meet the latest requirements of Industry 4.0. The exclusive design of the heat exchanger ensures high efficiency (94-96%) and easy maintenance. Made from stainless steel, it guarantees long life even in heavy-duty working conditions and with both mains and demineralized water. The price gap between gas and electricity makes gaSteam the ideal choice for more demanding applications, where steam is required for many hours a day.

Continuous modulation of steam flow-rate means this unit is also suitable for precision applications. Easy to install, it features a room-sealed combustion chamber with premix burner and gas control valve with double safety closing; it is moreover equipped with multiple safety devices and comes with ETL and CE certification (attested by TÜV-DVGW). The steam and flue gas outlets are pre-assembled, with constructional features to minimise the units’ footprint, allowing installation up against a wall. gaSteam features easy and immediate configuration and operation, thanks to the graphic touchscreen display and a simple and intuitive configuration wizard.

ultimateSAM

The ultimateSAM system can use steam both from a network under pressure and from an atmospheric pressure generator (humidifier). In the first case, the fluid reaches the distributor via a regulating valve, by means of which there is an expansion that almost reaches atmospheric pressure. In the second case, ultimateSAM is connected directly to the steam producer; in this case the modulation of the flow of steam is carried out directly by the humidifier. In order to minimize condensation, the lances for the distribution of steam have been designed with deflectors and nozzles so as to ensure that only dry steam is released into the air handler unit/duct.

The vertical air distribution pipes can be equipped with air gap insulation to reduce both parasitic heat gain in the air and condensate formation. The distributors with insulation have press-fitted nozzles in the pipes, which take the dry steam from the center of the distributors to avoid delivering droplets of condensate into the air flow. Non-insulated distributors do not have nozzles. The use of models with insulated lances with nozzles allows a reduction of 30% condensation compared to non-insulated ones. In both cases, of course, a short absorption distance is guaranteed (of the order of 200mm).