Plate and Frame Heat Exchanger

Superchanger

The SUPERCHANGER Plate And Frame Heat Exchanger, sometimes referred to as a gasketed plate heat exchanger or GPHE, provides outstanding efficiency transferring heat from one liquid to another, often water to water, or from steam to liquid. This modular exchanger combines frames, plates and connections to form a variety of configurations.

KEY FEATURES

- INDUCED TURBULENCE

- REDUCED FOOTPRINT

- HIGHLY VERSATILE

- TEMPERATURE APPROACHES

- EASY ACCESSIBILITY

- MAXIMUM FLUID COMPATIBILITY

Plate and Frame Heat Exchanger

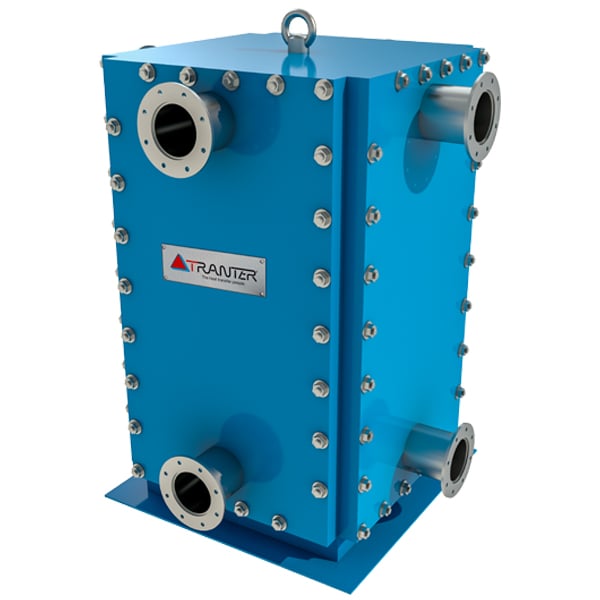

Shell and Frame Heat Exchanger

Supermax

The SUPERMAX® Shell And Plate Heat Exchanger is designed as a performance upgrade over shell and tube, block-type welded and brazed aluminum heat exchangers. The unit can overcome footprint constraints, extreme pressures/temperatures, fouling/scaling conditions and corrosive attack with liquids, gases, steam and two-phase mixtures.

KEY FEATURES

- REDUCED FOOTPRINT

- WIDE TEMPERATURE/PRESSURE RATINGS

- EXCELLENT THERMAL PERFORMANCE

- OUTSTANDING UPTIME

- SMALL HOLD-UP VOLUME

- TWO-PHASE FLUID FLEXIBILITY

Shell and Frame Heat Exchanger

Welded Plate Heat Exchanger

NovuBloc

Available for global energy intensive markets, the NovusBloc® welded plate heat exchanger encompasses a Tranter premium design concept offering a significant boost in heat exchange performance and durability for these processes.

- NOVEL PLATE DESIGN

- REDUCED UNIT SIZE

- FOUR MODEL SIZES

- WITHSTAND CHALLENGING CONDITIONS

- INCREASED DURABILITY

- FULLY ACCESSIBLE FOR CLEANING