- Expansion Joints and Compensators

- Expansion Loops and Hose Assemblies

- Piping Accessories

- Exhaust Bellows

- Metal Bellows and Assemblies

- Delegated Design Service

Mago Mechanical Sales is the exclusive manufacturers’ representative of Flex-Weld products. Our years of expertise in serving industrial, HVAC, and mechanical markets, allows us to be the perfect partner to represent Flex-Weld’s premium expansion joints, flexible connectors, and custom-engineered solutions. You can expect fast, localized support for Flex-Weld products, expert guidance in selecting the right solutions for your applications, and seamless communication between your team and Flex-Weld’s engineering experts. Whether it’s metal expansion joints, rubber connectors, or braided hose assemblies, Mago Mechanical Sales is ready to help you get the right product for the job-on time and built to last.

Expansion Joints & Compensators

For more than 100 years, Keflex has been designing and manufacturing metal bellows expansion joints for the HVAC industry. Keflex is considered a pioneer in leading the way with their innovative multi-ply bellows designs. Manufactured in accordance with EJMA guidelines that meet your HVAC and mechanical piping project specifications, Keflex expansion joints and 7Q series compensators are exclusively manufactured by Flex-Weld Inc., a division of Kelco Industries at their Woodstock Illinois facility.

Expasnsion Joints & Compensators

30MC Series Bellows and Expansion Joints

Flex-Weld 30MC Series General Purpose / Low Pressure Expansion Joints, are available in sizes 4” through 42”. Multi-Ply Stainless Steel Bellows construction, movement rated at 30,000 cycles plus. Manufactured to order for your specific application requirements. Available options include Flanged, Weld, or Groove Ends. Internal Flow Liner, Control Rods. Single, Dual, or Triple Bellows designs available for increased movements. Manufactured with 304SS, 321SS, or 316SS materials. Well-suited for a variety of applications including Wastewater Treatment, Construction, Generators, Exhaust, Aeration, Energy, and Marine. 30MC series available as fully welded expansion joints or as a bellows only, ready for your fabrication.

30MC Series Bellows and Expansion Joints

7Q Series Quadra-Side Expansion Compensator

The original heavy-duty Keflex™ 7Q Expansion Compensators are specifically designed for high pressure service, available in sizes ¾” to 4″, in both single and dual units. The single type can absorb 2″ total movement, 1 ½” in compression and ½” in extension from the factory predetermined setting. The dual type can absorb 4″ total movement, 3″ in compression and 1″ in extension from the factory pre-determined setting.

The heart of the Keflex™ 7Q Expansion Compensator is the multi-ply type 316L corrosion-resistant stainless-steel bellows. These bellows are internally pressurized and operate primarily in compression where they have the greatest hoop strength capability.

The Quadra-Side® square telescoping shrouds encompass the bellows to provide protection against torsion, squirm, misalignment and external damage, as well as preventing over-compression of the bellows. Additionally, the unique design provides visual evidence that the traverse of the unit has not been exceeded. The integral guiding feature of the Quadra-Side® prevents offset to assure the pipe movement is directed axially into the bellows, a requirement for optimum performance.

The square telescopic shroud does not serve as a chamber to contain liquid, or gas as do the covers on some other high pressure “compensators”. Therefore, the outside diameter of the Quadra-Side® type compensator is considerably smaller, permitting it to be installed in walls, under floors or behind radiator covers without expensive modifications at the point of installation.

7Q Series Quadra-Side Expansion Compensator

308/311 Series – Expansion Joints

The Original Multi-Ply Expansion Joint – Always Ask For Keflex™

Keflex™ 308 and 311 Series Multi-Ply Expansion Joints are the premier expansion joints in the industry. They offer the ultimate solution to piping thermal expansion problems. A wide variety of end configurations are available, and pressure ratings range from vacuum to 600 PSI at room temperature. Designed and manufactured in accordance with EJMA standards.

A variety of materials are also available for any type of media, including highly corrosive acids or gases. Keflex™ Multi-Ply Expansion Joints have a softer spring rate compared to other expansion joints with the same dimensions, making them easier to install, and requiring less force to actuate in service. The inner section of the engineering brochure, accessed through the link below, highlights the advantages of the multi-ply construction.

308/311 Series – Expansion Joints

Externally Pressurized Expansion Joints

MULTI-PLY SAFETY FACTORS-

In a critical application, a multi-ply expansion joint can, in most cases, preclude a catastrophic failure. If a failure occurs in one ply due to corrosion or fatigue, the intact plies will work as a protective barrier to contain the pressure and the medium until a replacement can be made. Flex-Weld multi-ply expansion joints are designed to provide utmost safety in the event of system failure. The burst pressures are a multiple of the operating pressure making the Flex-Weld multi-ply bellows the most reliable component in the system.

CYCLE LIFE OPTIMIZATION-

The technical advantage of using multiple plies of thin wall thickness material is that less residual stresses are introduced at the time the bellows were formed. Overall, Flex-Weld multi-ply expansion joints have lower built-in and induced stresses which ultimately results in longer cycle life. Also, the thinner gauge multiple plies have less localized induced stresses during operation compared to a single thicker ply. The configuration of the convolutions (pitch, depth, contour, number of plies, ply thickness) of FLEX-WELD multi-ply expansion joints are optimized to offer the highest fatigue life.

COMPACT DESIGN-

Multi-ply expansion joints have more flexibility than conventional single-ply expansion joints and thus require less live length to accommodate a given movement. The live length of the bellows can be minimized to absorb a given combination of axial, lateral and angular movements. This results in an economical, compact assembly which can be installed in a minimal amount of space. An additional benefit is a small effective area, resulting in lower thrust pressures on the anchors and mechanical equipment in the system. LOWER THRUST FORCES – The multi-ply design results in lower spring rates. Also, the effective cross-sectional area of multi-ply expansion joints is less, compared to single-ply bellows, to accommodate a given movement. These two reductions result in lower forces and moments on the anchors, equipment and guides. A side benefit is that fewer anchors and guides will be required in the overall bellows piping system.

Externally-Pressurized Expansion Joints are Designed to Replace:

- High-Maintenance Packed Joints

- Space-Confining Pipe Loops

- Costly Equalizing Expansion Joints

Externally Pressurized Expansion Joints

3150 Series Compact Expansion Joint

The Keflex™ 3150 Series compact Expansion Joint is designed to meet applications that require pressure ratings up to 150 PSI in a shorter length. This is achieved using 3 or 4 plies of heavier gauge stainless steel than is used in our lower pressure rated products. The 3150 series is available for pipe sizes from 2″ up to 12″, as a bellows only component ready for your fabrication, or a fully welded Expansion Joint. These bellows are ideal for OEM’s or repair facilities looking to add desired connections or to simply weld the bellows in place for your application. Keflex™ can also create ready to install custom assemblies using these standard bellows and then installing to customer specification flanges or any other type of connection. Please contact your Mago Mechanical Sales representative for additional details on custom assemblies utilizing the 3150 Series Bellows.

3150 Series Compact Expansion Joint

Bellows-Type Pump Connector

Maximum vibration absorption, longest cycle life, soft spring rate, Ease of installation and maximum safety.

Keflex™ Bellows-Type Pump Connectors are designed to compensate for multi-plane axial, lateral and angular movement in non-torsional applications. They are intended for use in both suction and pressure lines to absorb mechanical vibrations caused by pumps, compressors and other pipeline equipment. Bellows-Type Pump Connectors aid in compensating for minor piping misalignment and helping to minimize the stress on your system.

Heavy-duty restraining rods and spacers assure protection against bellows distortion in the event anchors are not properly secured. Keflex™ shatter-proof spacers absorb mechanical vibration without hampering axial, lateral or angular movement of the pump connector.

Multi-ply bellows were pioneered by Keflex™. The standard product has a minimum of four (4) plies, but the larger diameter models are constructed with up to sixteen (16) plies. Most of the bellows-type pump connectors provided by competitors are produced “offshore” with only one (1) or two (2) plies.

Unlike rubber and elastomeric connectors, multi-ply laminated stainless steel bellows capsules are not subject to premature deterioration resulting from elevated temperature conditions or UV exposure. Thus, they offer a longer cycle life in a wide variety of temperature applications ranging from sub-zero to super-heated steam. In the latter case, it may be necessary to include the optional internal liner to prevent excessive flow velocity from damaging the assembly. (Available on welded-flange units only)

Standard units are designed for a total axial traverse of 5/8” (1/2” compression, 1/8” extension), a total lateral movement of 1/8” (1/16” each side of centerline), and an angular offset of 3-1/2 degrees maximum. Custom-built assemblies are available to meet conditions beyond these specifications.

Flanged-type series 150, 151 and 301-1215 assemblies from 2” to 12” ID measure a compact 5.0” face-to-face to save valuable space. Sizes of 14” ID and up measure 9.0” face-to-face. Custom lengths are always available. Welded flange-types 1512 and 3012 are 6” face-to-face OAL for sizes up to and including 8”. They are intended as replacements for short-style braided metal hose, rubber and elastomeric spool type expansion joints. For sizes 10” and larger, the standard OAL is 8” face-to-face. Lengths other than standard are available upon request.

Rubber Expansion Joints

Keflex has a wider array of material and configuration types for rubber expansion joints than any other manufacturer. Their products are designed and engineered to carry a variety of media in pressure or vacuum applications. They absorb destructive system vibration and will contract or expand in response to pipe motion induced from thermal expansion and contraction.

Keflex offers all types of rubber expansion joints from single sphere to triple, floating flange to cable-tied. We offer standard sizes and diameters in addition to custom lengths and reducers. Materials range from the standard Neoprene and EPDM to PTFE. Keflex’s in-house molding, custom ducting assembly lines and offshore proprietary sourcing provide several manufacturing options.

Flex-Weld, Inc. / Keflex™ will design, engineer and fabricate your expansion joints to meet the unique requirements for each application. They can cross-reference to any existing product or redesign to fit a new system requirement. Contact your Mago Mechanical Sales representative for more information.

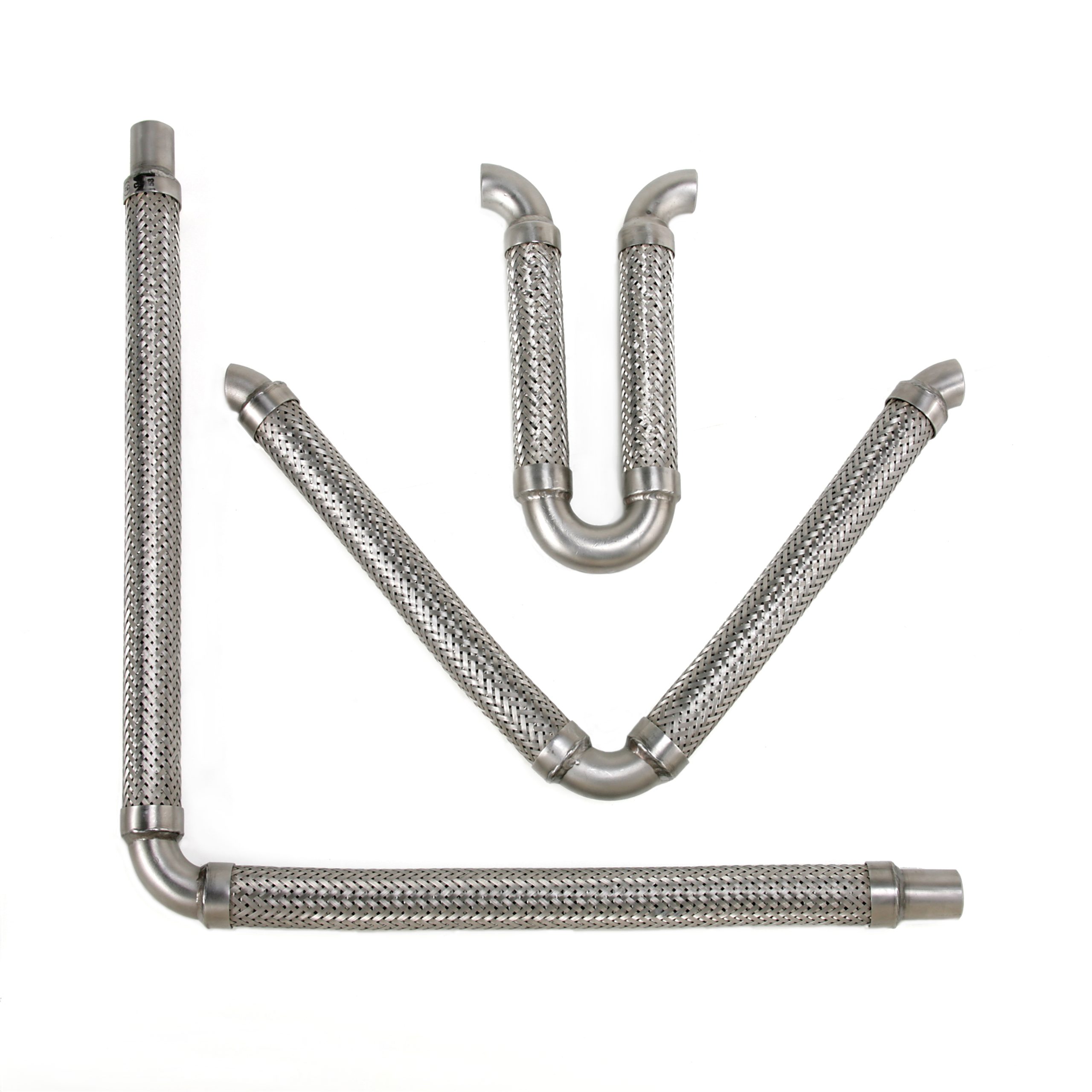

Expansion Loops & Hose Assemblies

Expansion Loops compensate for thermal and seismic movement in piping systems, allowing motion in all three planes while also reducing the stress on your mechanical piping and equipment. Expansion loops offer a space-saving option to replace hard pipe loop systems; they also create a lower end thrust load while requiring fewer pipe guides than traditional in-line style expansion joints. Keflex’s straight flexible metal hose and pump connectors handle the stresses of vibration and offset within your piping system and are available in industry standard and custom made to order configurations for higher pressure, larger amounts of movement and upgraded material options are also available. Keflex’s flexible connectors are UL listed for NSF-61/NSF-372.

Expansion Loops & Hose Assemblies

Braided Hose Assemblies

For vibration absorption and the elimination of piping stress in HVAC applications, Keflex™ Gold and Silver Series braided flexible pump connectors are manufactured from 300 Series stainless steel annular corrugated metal hose surrounded with a 300 Series wire braid of high tensile stainless steel. This combination provides a corrosive-resistant flexible braided pump connector with a longer service life than lighter duty type connectors. Customized assemblies are made to order with the following options: overall length, double braid for higher pressure needs and a variety of end fitting types including Groove or Weld ends. Contact your Mago Mechanical Sales representative for more information.

Straight Flex Connectors UL/Fire

Approved for use throughout your fire sprinkler piping systems, these UL listed flex connectors takes stress off your equipment by compensating for vibration, misalignment, and lateral offset.

Available in varying lengths to meet your offset needs, our UL flex connectors also come in a variety of end fittings for easy installation.

Straight Flex Connectors UL/Fire

Expansion Loops

Keflex Expansion Loops compensate for thermal expansion in all types of piping systems and allows for random and unpredictable seismic movements as well as excessive offset and lateral movement. Reducing and/or eliminating stress and strain protects and increases longevity of equipment and piping. Keflex Expansion Loops feature an in-the-wall design, substituting bulky traditional expansion joints. This provides an access for easy pipe maintenance and condensate draining.

SPECIALTY APPLICATIONS:

- High pressure systems

- Ultra-purity cleanliness.

- Corrosive environments.

Advantages over conventional bellows-type expansion joints:

- Less space required.

- Easier to install.

- Fewer anchors and guides required.

Expansion Loops UL/Fire

UL Listed, Fire Rated Expansion Loops compensate and allow for random, unpredictable seismic movement, thermal growth, excessive offset, axial, or lateral movement within your sprinkler piping systems. Available in Flanged, Grooved & Male threaded end configurations and in a variety of movement and material type options. Expansion loops offer a space saving solution and can be installed easily where building or pipe movement would be expected. Contact your Mago Mechanical Sales representative for a quote.

Specialty Application:

Mechanical Piping, Sprinkler systems

Advantages over conventional bellows-type expansion joints:

- Less space required.

- Easier to install.

- Fewer anchors and guides required.

Heat Pump/Water Hose

Available in steel, stainless, and aluminum Braided hose: stainless steel outer braid covering and EPDM core Male & Female fittings: 1/2” – 1” Brass, 1-1/4” – 2” Steel Gasket: Fiber Washer.

Maximum temperature range 25° / 195°F.

Hose assemblies are intended for water use only.

This is a fire rated flexible connector.

Hose fittings available: fixed male x male swivel and fixed male x female swivel.

Lengths available from 12” – 48” in 6” increments.

Contact your Mago Mechanical Sales representative for custom lengths and sizes.

Piping Accessories

Keflex™ products perform under the most demanding conditions. Keflex™ pipe guides, anchors and brackets are designed to ensure positive pipe alignment by restricting lateral pipe movement while allowing for movement along the axis of the pipe. Used in conjunction with expansion joints, loops and compensators, Keflex™ pipe guides protect the integrity of the pipe, expansion devices and mechanical equipment for optimum performance. Refer to installation instructions for proper placement of pipe guides and anchors in accordance with EJMA guidelines.

Anchor Clamps

Select Keflex™ Anchor Clamps for no-load or low end thrust load expansion joints. Keflex™ Anchor Clamps are well-suited for installation with our Keflex expansion loops. These anchor clamps are lightweight, fabricated from ASTM A-36 steel and manufactured in the USA. Keflex™ anchor clamps include 2 brackets for quick and easy installation. Anchor clamps are not suitable for in-line bellows type expansion joint installations.

Anchors

In accordance with EJMA standards, the proper installation of Anchors and Guides are essential to restraining your piping systems and ensuring your expansion joints and compensators will function properly, as designed. Main anchors are necessary at the end of each pipe run, with guides installed to prevent the line from bowing, buckling or becoming misaligned because of thermal expansion or internal pressures. Pipe hangers and rollers are not considered to be adequate as guides. The main anchors must restrain the ends of the pipe so that all expansion is directed into the compensator. The main anchors must also withstand the end thrust force of the internal pressure. This force is shown in the Thrust Force Data Table. Compensators should not be subjected to hydrostatic pressure tests beyond their rated working pressures. If a higher-pressure test is required, the factory should be advised. The inside of all piping must be clean before installing and testing compensators. Before the pipelines are hydrostatically tested, all anchors and pipe guides must be secured. The contractor installing sweat end type compensators is advised to use a soft solder. Excessive heat used to make the solder joint may have a detrimental effect on the compensator. Soldered joints should be washed thoroughly to neutralize or remove acids used in solder fluxes.

Pipe Guides

Keflex™ pipe guides are designed to ensure positive pipe alignment by restricting lateral pipe movement while allowing for movement along the axis of the pipe. The pipe guide consists of a spider guide that is clamped to the pipe where movement is to be restrained. The guide body is anchored. The spider moves through the body as the pipe expands and contracts along the axis of the centerline. The pipe movement is directed into the expansion device for problem-free operation. Used in conjunction with expansion joints, loops and compensators, Keflex™ pipe guides protect the integrity of the pipe, expansion devices and mechanical equipment for proper operation.

Key Benefits:

- All guides are constructed of carbon steel and coated for protection.

- Spider-housing design ensures positive pipe alignment, protecting pipe, expansion devices, and mechanical equipment.

- Bolted, split-housing construction is designed for easy assembly.

- Axial movement selection is specific to application requirements.

- Orders shipped unassembled for fast field installation.

- Pre-insulated models match insulated system piping to reduce time and labor on the job. (Requires field assembly.)

Exhaust Bellows

Flex-Weld, a division of Kelco Industries, is a premier metal expansion joint manufacturer and exhaust bellows supplier. Flex-Weld designs and fabricates flexible metal components and precision-engineered products to our customers’ specifications. Our custom metal exhaust bellows, exhaust system components, and flexible metal hose assemblies work overtime to reduce noise and vibration and compensate for thermal pipe expansion and contraction. Our single- or multi-ply fabrication capabilities allow for a wide range of technical requirements while our proprietary techniques result in flexible metal components with a much higher cycle life and lower spring rates:

- Metal Expansion Joints

- Metal Exhaust Bellows

- Bellows Exhaust Pipe

- High Temperature Expansion Joints

- Engine Exhaust Bellows

- Custom Metal Expansion Joints

- Diesel Engine Exhaust Pipe

- High Pressure Pipe Systems

- Marine Exhaust Fabrication

- Exhaust Capsules

Metal Bellows & Assemblies

Flex-Weld, Inc. is a premier manufacturer of metal bellows and bellow assemblies with over 100 years design and manufacturing experience in the production of precision-formed OEM and custom metal bellows and bellows assemblies for motion and flow control. AS9100D with ISO 9001:2015 Quality certified.

Flex-Weld bellows can be designed for any application or market including construction, manufacturing, medical, engineering, security, agriculture, aerospace, renewable energy, transportation, industrial and chemical, food and beverage, water reclamation, and HVAC. We offer a wide range of material thickness and types including all grades of stainless steel as well as Hastelloy, Inconel, Monel and Titanium.

Whether the bellows are used in an industrial or precision valve application or are used to convey chemicals in a dangerous or hazardous environment, our bellows are designed and built to perform. Single or multi-ply fabrication capabilities allow for a broad range of pressure, cycle life, or spring rate requirements. Choose from safety relief valve bellows, butterfly valves, mechanical seal bellows, valve stem bellows, bellows assemblies, or Request a Quote for your precision bellows needs.

Delegated Design Service

For over 100 years, Keflex™ has been a leading manufacturer of HVAC products and now offers a review of your design/build or plan and specification projects. Keflex’s™ experienced team of professional engineers will provide you with the proper project solutions and peace of mind by adhering to Expansion Joint Manufactures Association Standards. All Professional Review Services Packages include a design, sealed by a licensed engineer, in accordance with Industry Codes and Standards to comply with local, state, and federal regulations.

Keflex™ Professional Review Service will conduct stress and flexibility analysis to ensure that your piping systems meet ASME B31 piping codes. A written report, calculation results and stress isometric drawings with recommendations will be provided for your project. Stress & Flexibility analysis, together with a detailed Mechanical Piping Review, will ensure that your mechanical system will function as intended for its useful service life.

Flex Weld offers Professional Review Services for your projects that require Delegated Design by a Licensed and Stamped Professional Engineer from your State. Our Professional Review Service will conduct stress and flexibility analysis to ensure that your piping systems meet ASME B31 piping codes.

Services Include:

- Design Layout

- Material Certifications

- Design Calculations

- Formal Submittals

- Locally “State Stamped”

- Overlaid existing plans

- Anchor and expansion calculations

- All installation instructions