In-Line Pumps

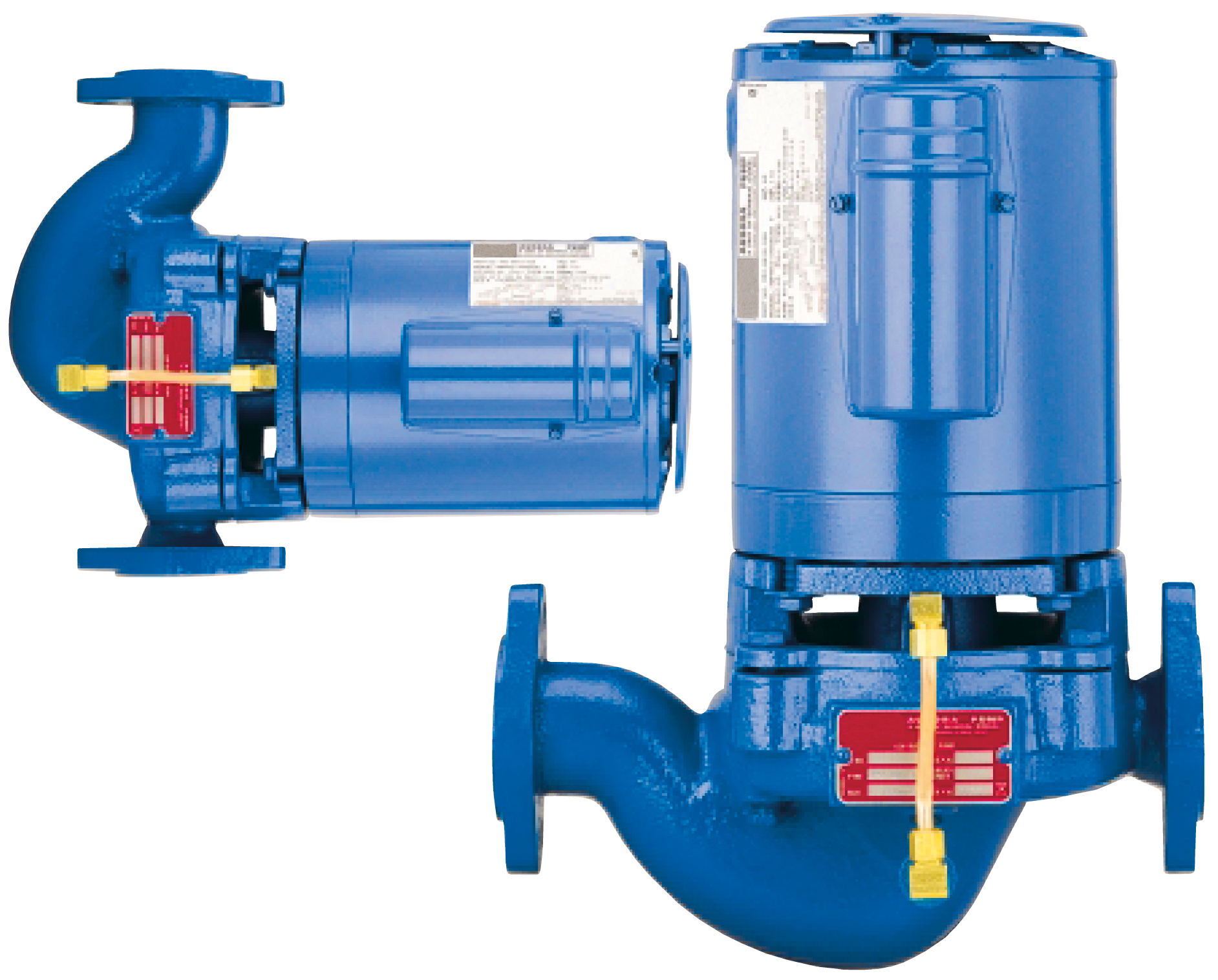

Pentair Aurora 1070 circulator pump

KEY FEATURES

- 3-Speed Wet Rotor Circulators:

- Conserve energy and eliminate maintenance

- Maximum fluid temperatures up to 230°F (110°C)

- Maximum working pressure is 140 PSI (965 kPa)

- Dry Rotor Circulators:

- Durable, versatile and designed for use in a wide range of applications

- Mechanical seals can be replaced in 5 minutes

- Maximum fluid temperatures up to 230°F (110°C)

- Maximum working pressure is 150 PSI (1030 kPa)

- 3-Piece Circulators:

- Standard, 3-piece design featuring radially-split body, over-sized shaft, centrifugal impeller, positive mechanical seal and modular construction

- Maximum fluid temperatures up to 225°F (107°C)

- Maximum working pressure is 175 PSI (1207 kPa)

- Custom In-Line Circulators:

- Radially-split body and can be left in the line while servicing the pump. This feature eliminates the need to disconnect pipes.

- Applications include hydronic heating and cooling, domestic water systems, multi-stage zoning and general industrial service

- Maximum fluid temperatures up to 225°F (107°C)

- Maximum working pressure is 175 PSI ( 1207 kPa)

Vertical Pumps

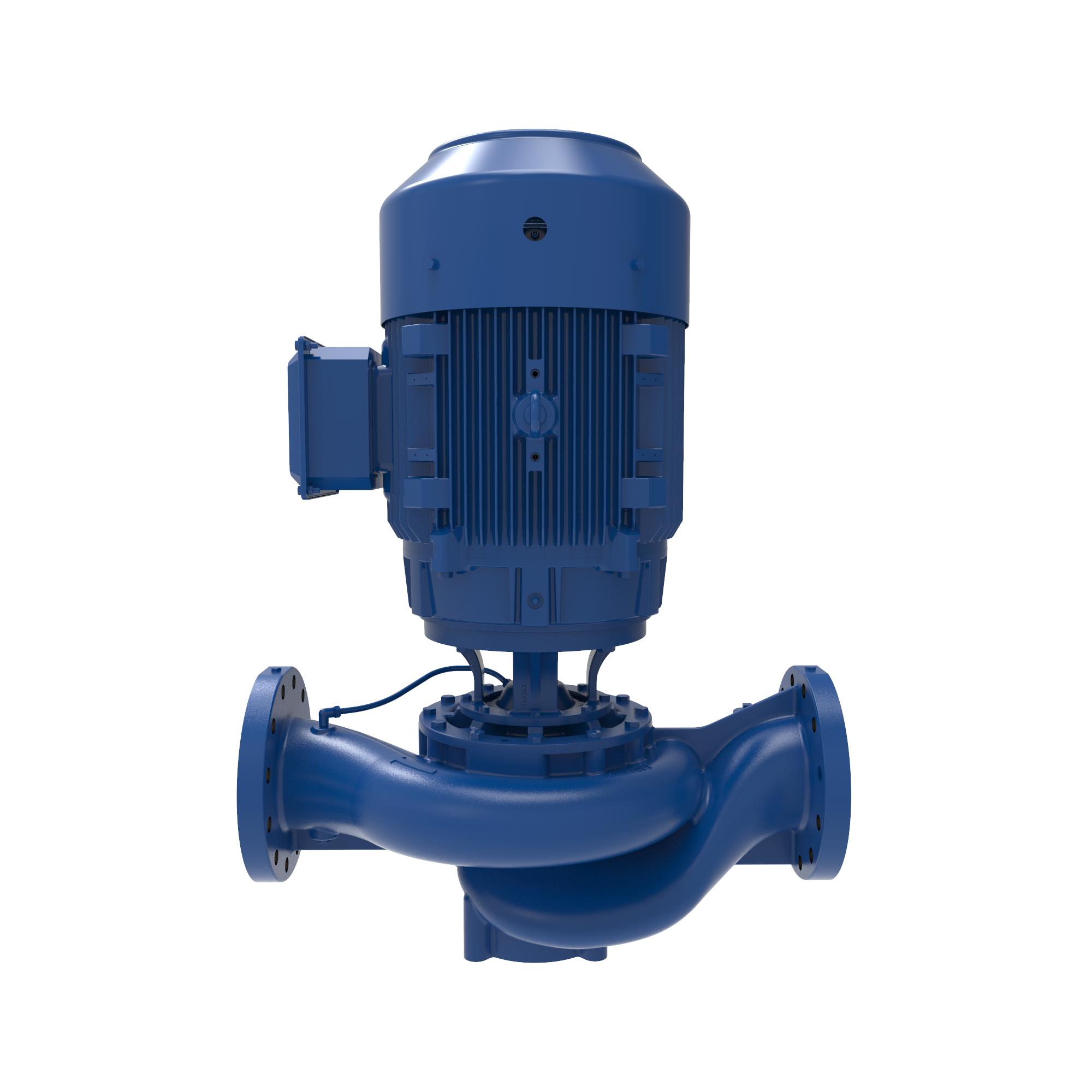

Pentair Aurora 382A and 382B Single Stage Vertical Close and Split Coupled Centrifugal Pumps

Today’s room space constraints are more challenging than years ago. Pentair Aurora Vertical In-Line Pumps are specifically designed for mounting directly in a pipeline and to reduce the space required in a pump room; two pumps fit in the space of one. These modern pumps with a clean, straightforward and updated design were developed with upgraded materials of construction and a simplified offering without limiting ranges of head and capacity requirements. These pumps not only feature shared hydraulics and premium materials as standard offering, but also offer industry leading durability.

- Mounts directly to piping.

- Higher working pressures, up to 290 psi.

- C-face bracket accommodates most common National Electrical Manufacturers Association (NEMA) rated motors.

- Patented jacking mechanism for quick and easy servicing.

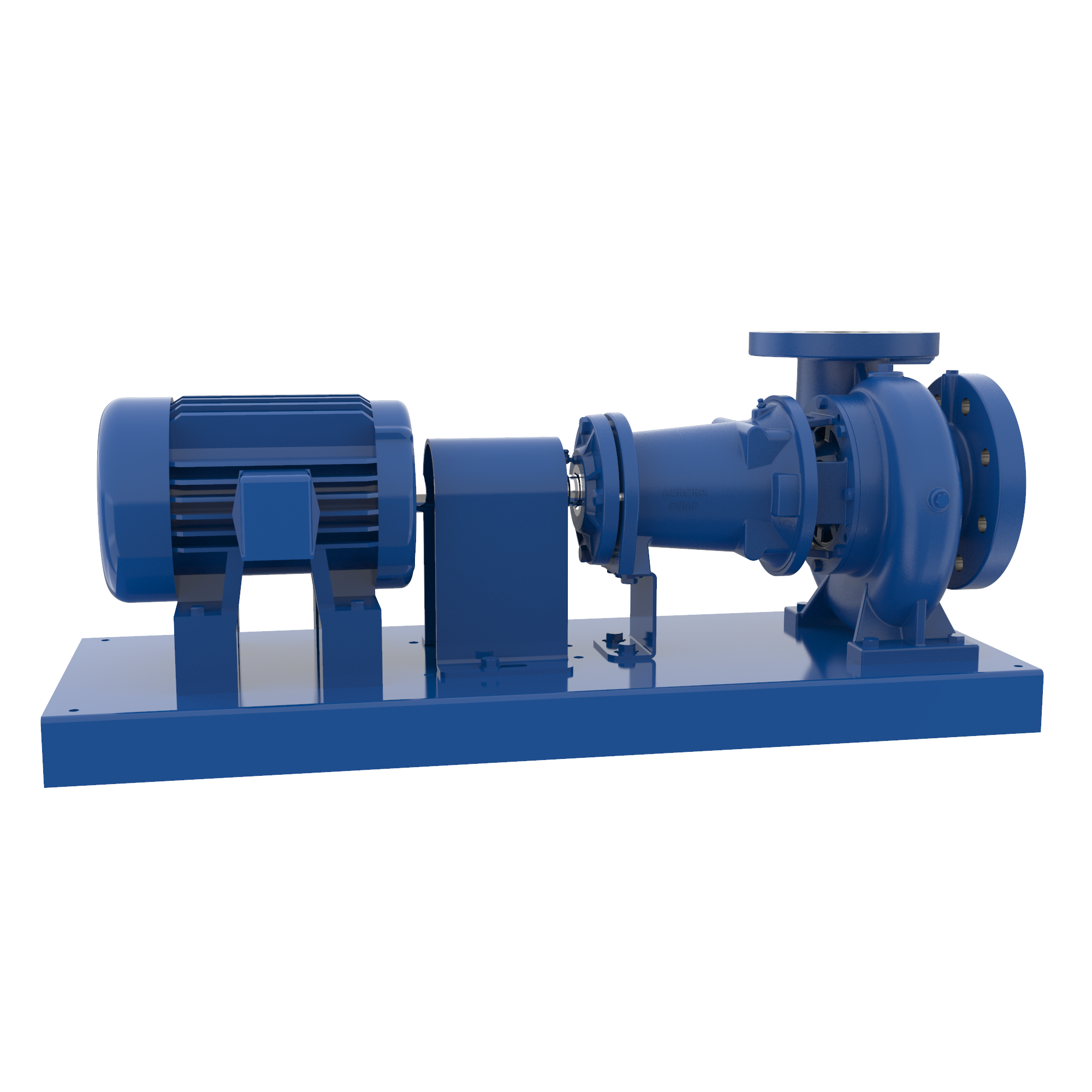

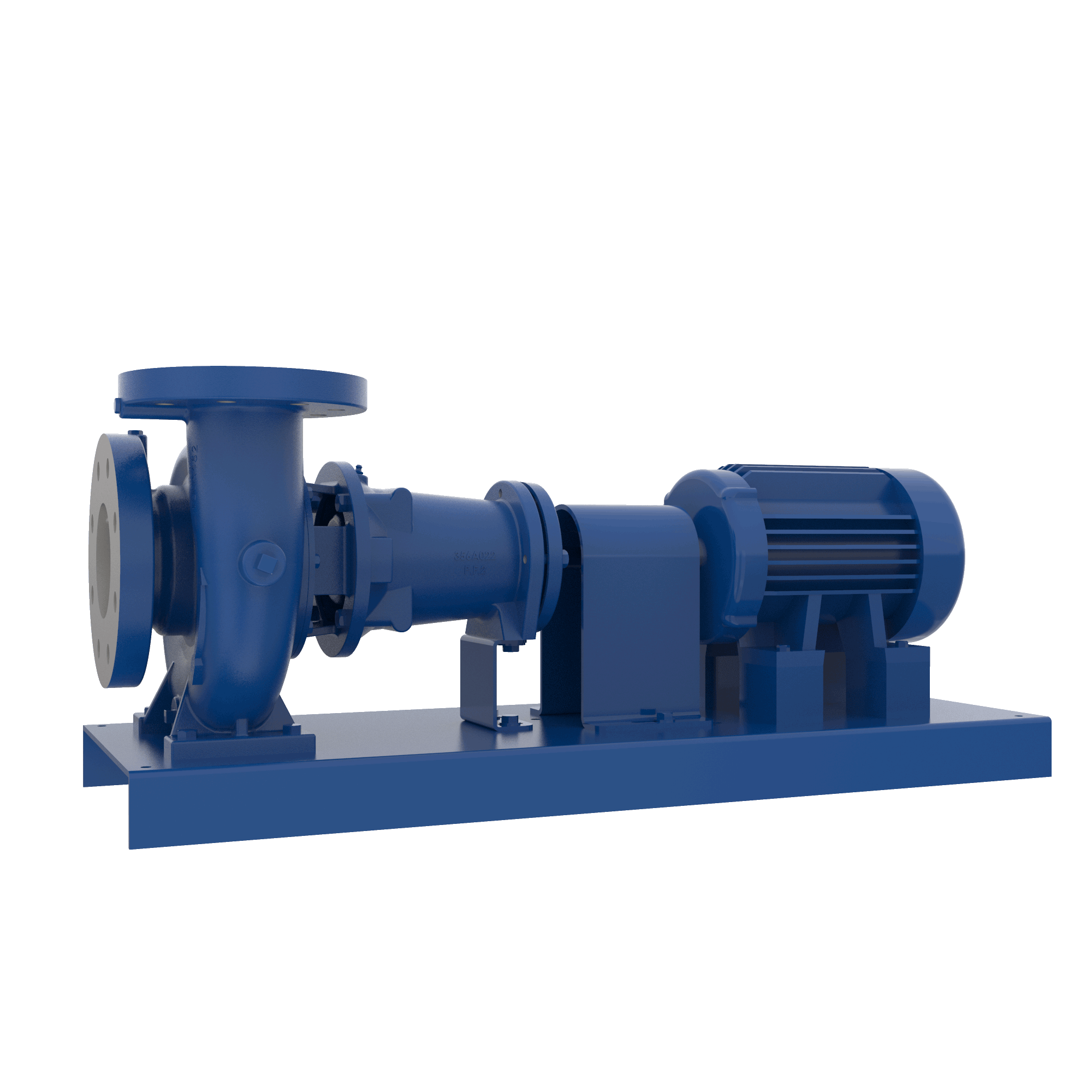

End Suction Pumps

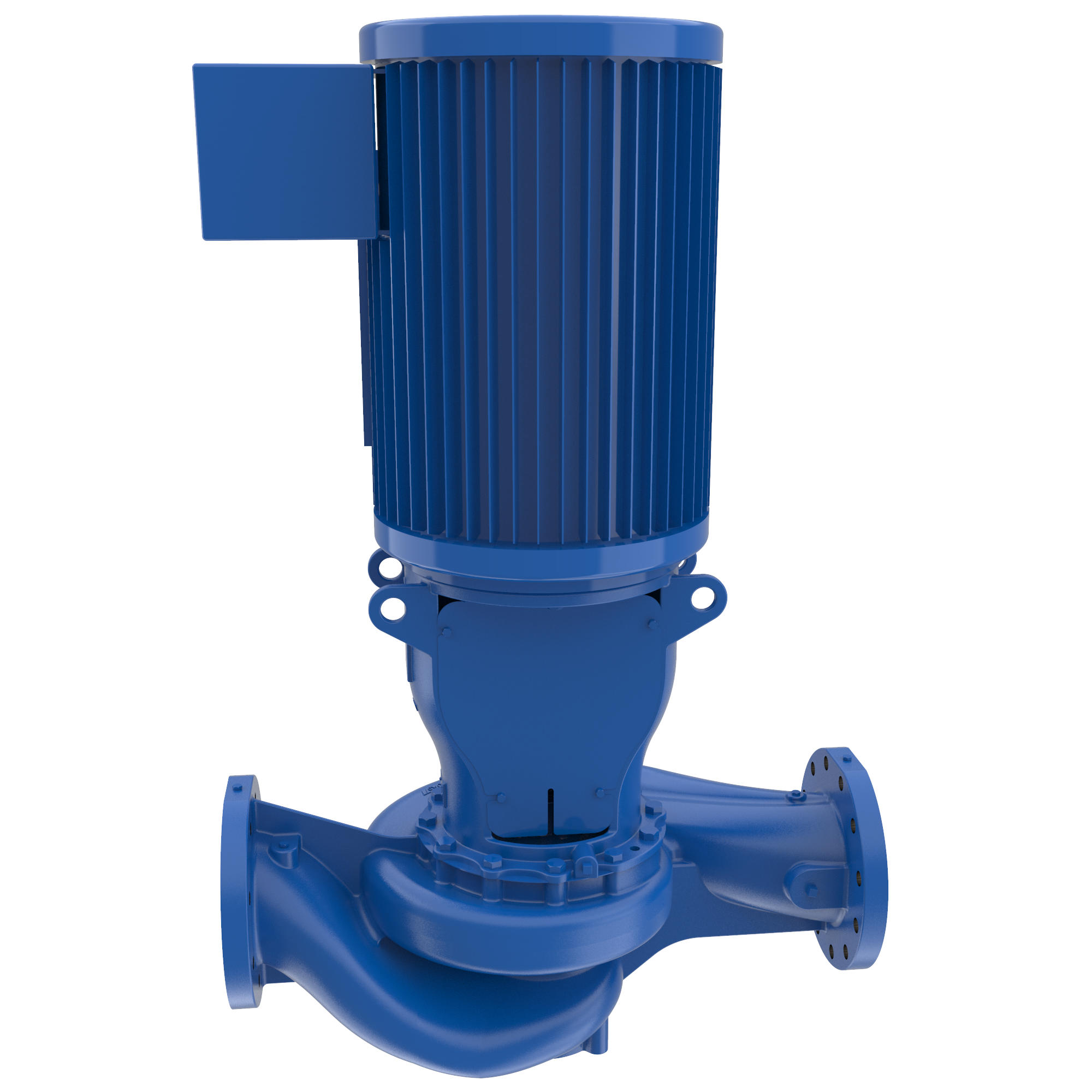

Pentair Aurora 3800 Series Single Stage End Suction Centrifugal Pumps

Liquid handling requirements have evolved over the years and have increased along with temperatures and pressures. Today’s installations demand sturdy but quiet, smooth running pumps with longer life cycles. These modern pumps with a clean, straightforward and updated design were developed with upgraded materials of construction and a simplified offering without limiting ranges and keeping maximum interchangeability in mind. These pumps not only feature shared hydraulics and premium materials as standard offering, but also offer industry leading durability.

- The sturdiest power frames in the industry

- Foot mounted and double volute

- Standard back pullout

- Direct replacement to the largest installed base

Horizontal Pumps

Pentair Aurora 421 Horizonal Two Stage Split Case Pumps

Aurora built its business on the split case pump more than 90 years ago. Today, we continue to improve upon our original design and manufacture quality pumps that outlast our competitors.

KEY FEATURES

- Model 421 is Horizontally Baseplate Mounted with a Driver Flexibly Coupled to the Pump

- Design Recommended where Space is Available and Flooding is Not Possible

- Interwoven, graphite/Teflon Lubricated Acrylic Yarn Packing Rings

- Coupling Guard on the Model 421

- Applications Include:

- Cooling, Heating and Air Conditioning Service

- Boiler Feed Service

- Condensate Service

- High Pressure Water Service

Horizontal Two Stage Split Case Pumps

Pentair Aurora 411 Horizontal Single Stage Split Case Pumps

KEY FEATURES

- More than 90 years ago, Aurora Pump built its business with these reliable and long-lasting pumps. We are still building on our legacy of quality design and manufacturing today.

- Horizontal Split Case Pumps are the Traditional Solution for Handling the Flow of Liquids

- 411 Models are Horizontally Baseplate Mounted with a Driver Flexibly Coupled to the Pump

- Design Recommended Where Floor Space is Readily Available and where Flooding is Not Possible

- Applications Include:

- Cooling, Heating and Air Conditioning Service

- Boiler Feed Service

- Condensate Service

- High Pressure Water Service

Horizontal Single Stage Split Case Pumps

Vertical Multi Stage Pumps

Pentair Aurora PVM (X) Series Vertical Multi-Stage Pumps

- Flow series: 1, 3, 5, 10, 15, 20, 33*,45,64,90,120,150

- Flanged, NPT or grooved connections

- Cartridge Mechanical Seal – can be replaced easily without dismantling the pump

- Continuous-duty, best in class, high efficiency designs

- Heavy-duty cast motor bracket insures proper motor alignment

- High-thrust TEFC enclosure motor options

- Versatility in performance and design

- Retrofits easily in existing and new installations, reducing valuable downtime

- Lower operating costs

- Typical Applications Include:

- Commercial Pressure Boosting

- Boiler feed, Condensate Systems

- Agricultural and Commercial Irrigation

- Pulp, Paper and Lumber Mining

- Petrochemical: Refinery and Offshore Drilling

- Car and Truck Wash Systems

- Jockey Pump for Fire Protection

Vertical Split Case Pumps

Pentair Aurora 412, 412C Vertical Single Stage Split Case Pumps

The split case pump has long been used for the handling of liquids where the utmost in reliability and accessibility is paramount. The 410 Series is a modern design based on Aurora’s over 90 years of experience with the design, sales and manufacturing of split case pumps.

KEY FEATURES

- Model 412 is vertically mounted using flexible shafting between the driver and the pump

- Model 412C is vertical chair-mounted

- Design recommended where floor space is limited and flooding possible

- Vertical split case pumps require half the floor space of a horizontal split case pump

- Inline piping arrangement allows for piping in any direction

- Elevated motor protects against potential flooding if the pump station is in a low area

- Applications include:

- Cooling, Heating and Air Conditioning Service

- Boiler Feed Service

- Condensate Service

- High Pressure Water Service

Pentair Aurora 413, 413C Vertical Single Stage Split Case Pumps

KEY FEATURES

- Model 413 Vertically Mounted with an Elevated Driver Coupled Directly to the Pump through a Flexible Coupline

- Model 413C is Vertical Chair-Mounted

- Design Recommended Where Floor Space is Limited and Possible Flooding Chances are Marginal

- Vertical Split Case Pumps Require Half the Floor Space of a Horizontal Split Case Pump

- Inline Piping Arrangement Allows for Piping in Any Direction

- Elevated Motor Protects Against Potential Flooding if the Pump Station is in a Low Area

- Applications Include:

- Cooling, Heating and Air Conditioning Service

- Boiler Feed Service

- Condensate Service

- High Pressure Water Service

Turbine Pumps

Vertical Turbine Pumps

KEY FEATURES

- Capacities to 50,000 GPM

- Heads to 2,000 feet

- Temperatures to 200° F

- Bowl Sizes from 4″ to 57″ diameter

Booster Systems

Pentair Aurora 790 CP Booster Systems with Stackable Pumps

KEY FEATURES

- Designed to Meet Variable Flows in High-Rise, Commercial, Municipal and Industrial Buildings

- UL Labeled Pressure Sensing Control Panel

- PLC Pump Sequence Controller

- Vertical Stackable Pumps

- Vertical Configurations

- Easy to Select, Install, Start-up

- Trouble-Free Operation

- Available in Duplex and Triplex Units for Quick Delivery

- All Units Performance Tested

- Applications Include:

- Potable Water

- Constant Pressure Booster System

- High Rise Building

Booster Systems – Stackable Pumps

Pentair Aurora 7710 Intelliboost Constant Pressure Variable Speed Booster Systems

KEY FEATURES

- Designed to Meet Variable Flows in High-Rise, Commercial, Municipal and Industrial Buildings

- UL Labeled Pressure Sensing Control Panel

- PLC Pump Sequence Controller

- Vertical Stackable Pumps

- Vertical Configurations

- Easy to Select, Install, Start-up

- Trouble-Free Operation

- Available in Duplex and Triplex Units for Quick Delivery

- All Units Performance Tested

- Applications Include:

- Potable Water

- Constant Pressure Booster System

- High Rise Building

Booster Systems – Variable Speed

Pentair Aurora 770 CP Boss Constant Pressure Booster Systems

KEY FEATURES

- Designed to Meet Variable Flows in High-Rise, Commercial, Municipal and Industrial Buildings

- PLC-based Systems Available in Horizontal and Vertical Configurations

- Easy to Select, Install, Start-up

- Trouble-Free Operation

- Available in Duplex and Triplex Units for Quick Delivery

- All Units Performance Tested

- Applications Include: Constant Pressure Booster System & High Rise Building

Booster Systems – Constant Speed

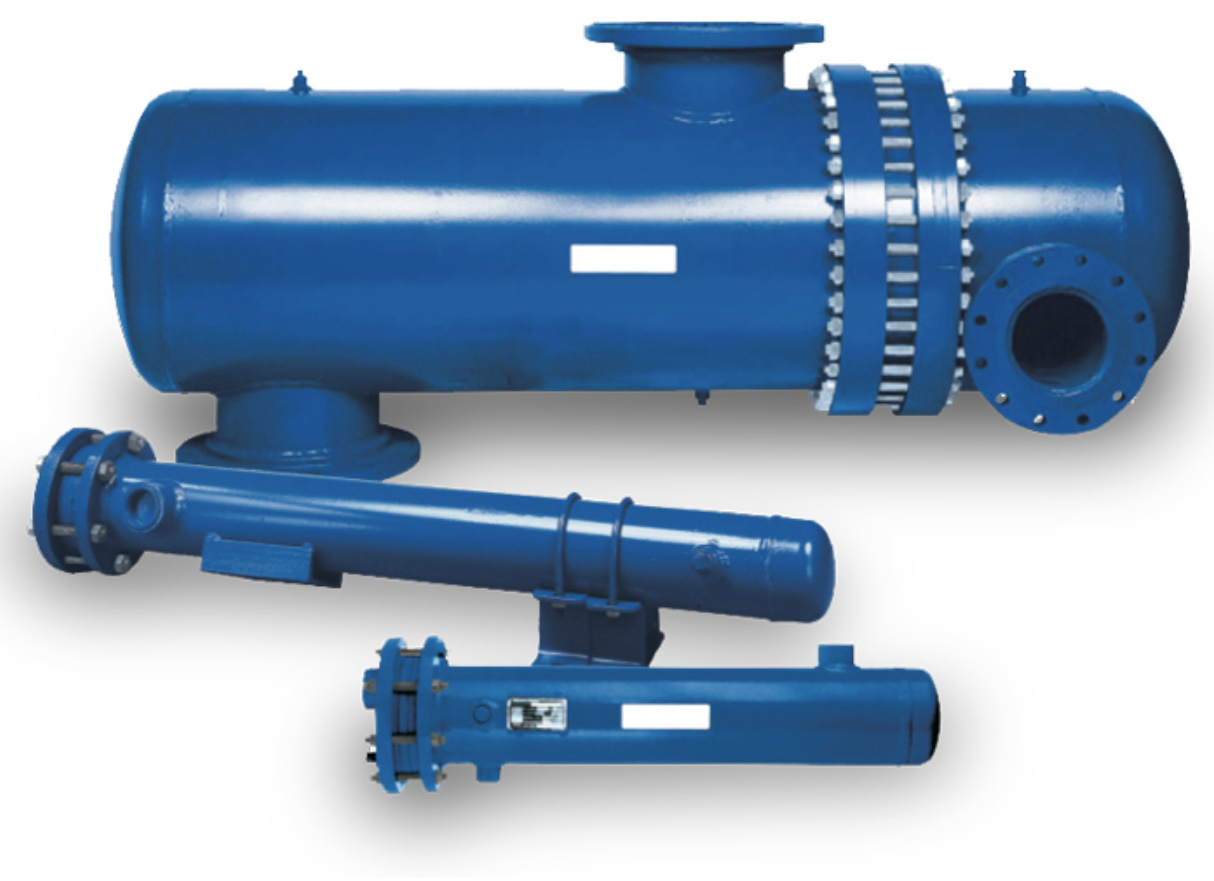

Heat Exchangers

Pentair Aurora 1080 Shell and Tube Heat Exchangers

KEY FEATURES

- Designed for commercial or industrial use with a broad range of applications where fluids must be quickly heated or cooled

- Aurora design meets the ASME Boiler Code Section VIII, Division 1

- Carbon steel components, copper tubes and a rugged cast iron head

- Heavy-duty U-shaped copper tubes2 and 4 pass construction

- 4″ to 30″ (102 mm to 762 mm) diameter in varying lengths

- 1080 – ST – water in tubes, steam in shell

- 1080 – STW – steam in tubes, fluid in shell: fluid in tubes and shell

Type 1080-ST, 1080-STW and U-Tube Heat Exchangers:

- Include a removable tube bundle as a standard feature

- U-shaped design provides long service life by eliminating the effects of thermal expansion and contraction

Type 1080-STX, 1080-STWX Double-Wall and U-Tube:

- Double-wall tubes are designed for applications where it is critical that the system prevents the mixing of internal fluids (i.e. potable water heaters)

- Fits the shell of an existing 1080-STW heat exchanger

Heat Exchangers – Shell and Tube

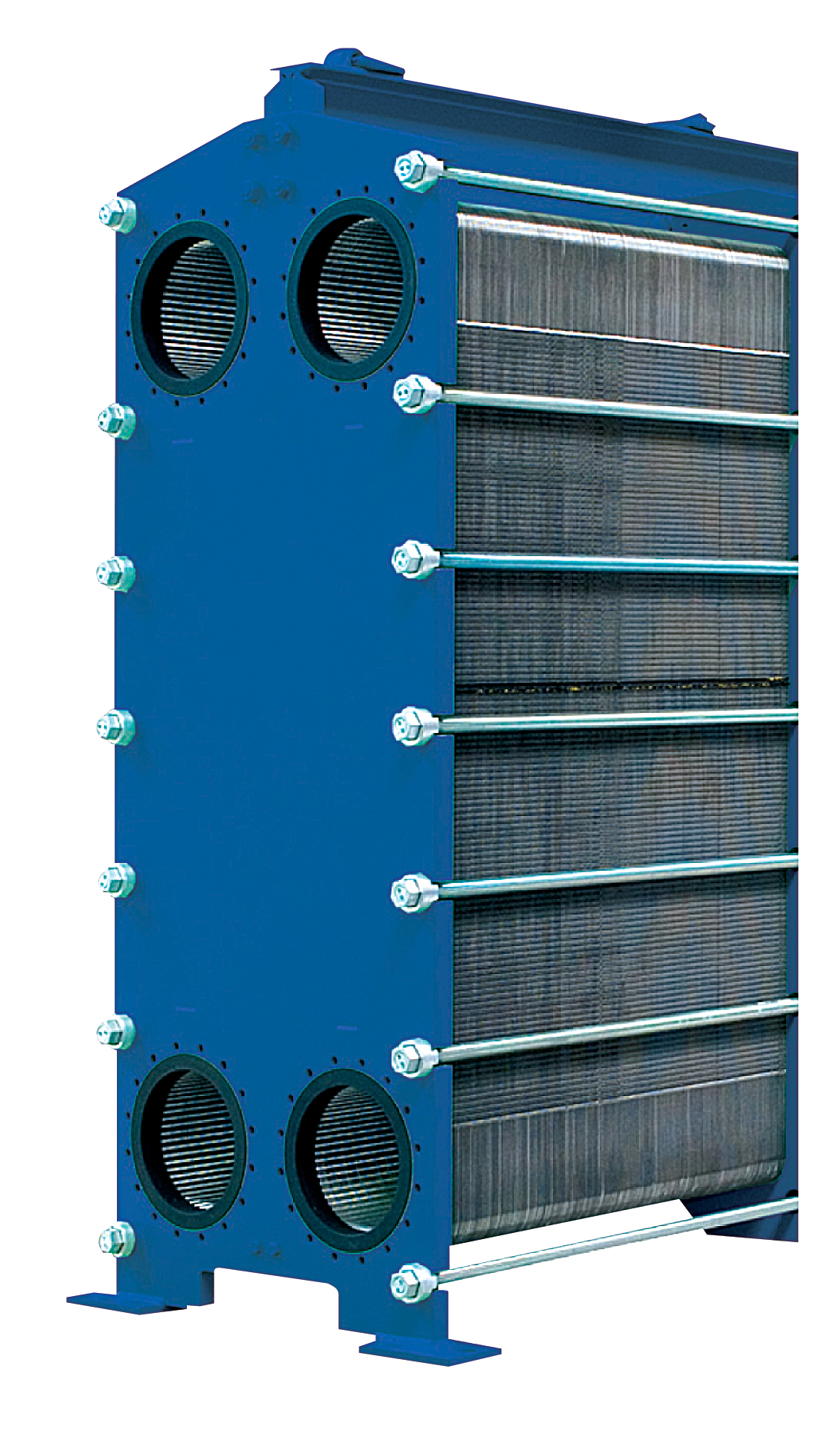

Pentair Aurora 1082PF Plate & Frame Heat Exchangers

Aurora’s Plate & Frame Heat Exchangers use corrugated plates creating more heat transfer with less materials. Gasketed plate and frame heat exchangers are used for liquid-to-liquid applications such as HVAC, chemical, sugar, marine, food, and renewable energy and power.

KEY FEATURES

- Gasketed plate and frame heat exchangers are used for liquid-to-liquid applications such as HVAC, chemical, sugar, marine, food, renewable energy and power

- Energy cost savings with corrugated plates creating more heat transfer with less materials

- Lower up-front costs for installation and maintenance thanks to fewer plates

- Quality construction and materials mean your purchase will last longer than other, similar heat exchange products

- Versatility in a wide-range of sizes, materials and configurations to fit your needs and the particular footprint of your product

- ASME and PED pressure vessel certifications

- 100% CFD Modeled plate design for optimal heat transfer

- ASME and PED pressure vessel certifications

- Wide-range of sizes, materials and configurations

- Made in USA

AURxx1 – AURxx5

- Maximum pressure is 300 PSIg

- Maximum temperature is 410°F (requires Viton, max temp for EPDM is 300°F)

- Maximum flow is 8,400 G.P.M. per HX

AURxx9

- Maximum pressure is 360 PSIg

- Maximum temperature is 410°F (requires Viton, max temp for EPDM is 300°F)

- Maximum flow is 4000 G.P.M. per HX

Heat Exchangers – Plate and Frame

Pentair Aurora 1081BP Brazed Plate Heat Exchangers

KEY FEATURES

- Brazed Plate Heat Exchangers are compact in construction taking up less space and weighing less than traditional heat exchangers

- Brazed plates create high performance heat transfer surface

- Versatility in a wide range of applications including radiant floor heating, domestic water heating, snow melt, swimming pools, steam, close approach, high pressure systems, shell & tube replacements

- Lower overall and up-front costs

- Lower costs for installation and maintenance

- ASME and PED pressure vessel certification

- Plate material is 316L Stainless Steel or marine stainless alloy (for steam, swimming pool water, sea water and ground water)

- Working pressure is 450 PSI (standard FP models) 300 PSI (marine, swimming pool, stearn models)

Heat Exchangers – Brazed Plate

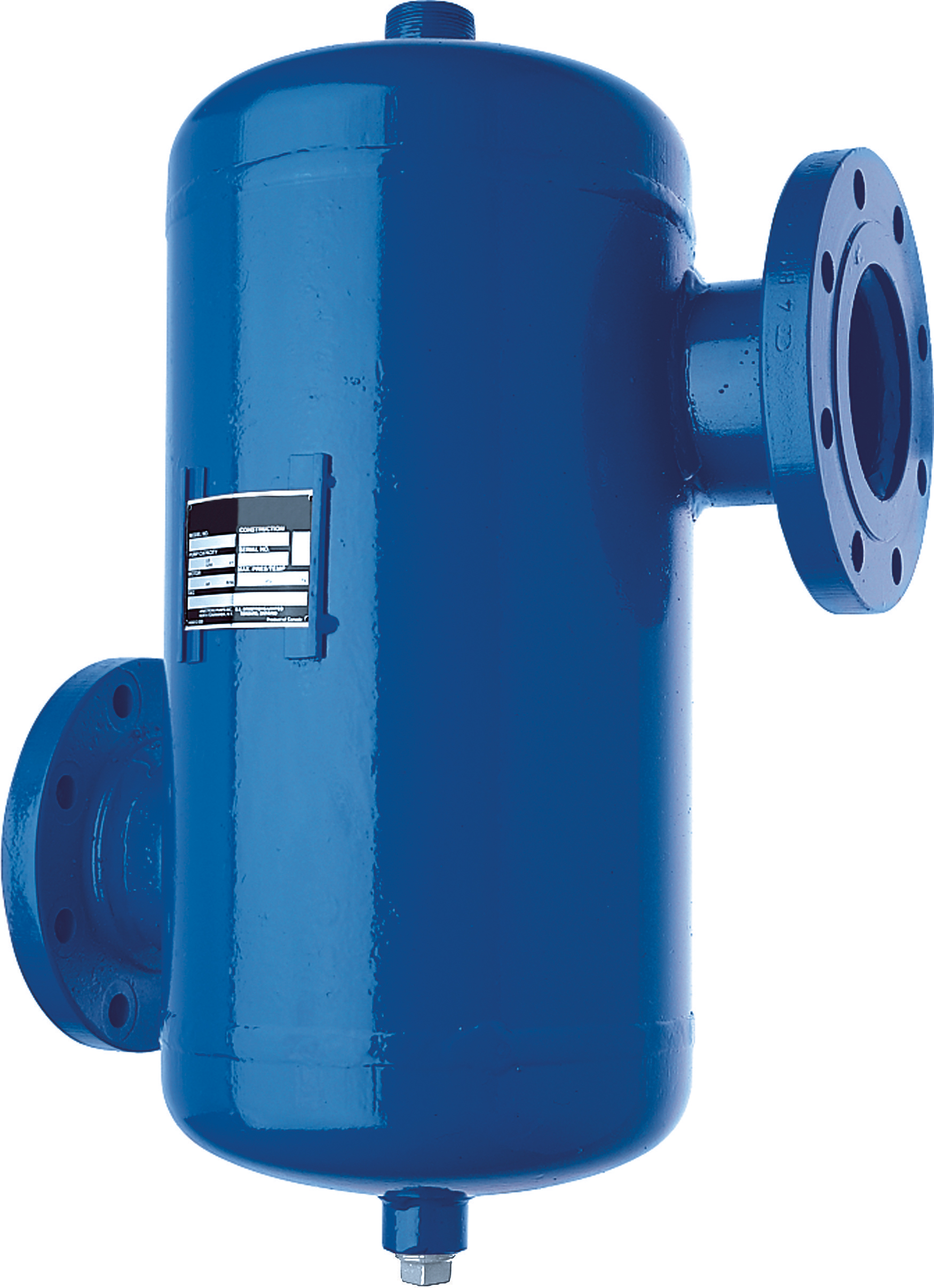

Suction Diffuser

Pentair Aurora 1030 Suction Diffuser

KEY FEATURES

- Designed for direct mounting on the suction flange of horizontal and vertical pumps

- Available in sizes 2″ to 17″

- Mounting the suction diffuser on any pump suction turns the piping 90° replacing an elbow

- Connects same-size piping to the pump suction but can also connect to inlet piping one size larger than the pump suction eliminating a reducing elbow

- Fine mesh brass start up strainer and permanent strainer

- Flow stabilizing vanes installed on the outlet allow the suction diffuser to bolt directly to the pump saving space and cost on a long straight pipe length

- Cast iron body and cover

Triple Duty Valves

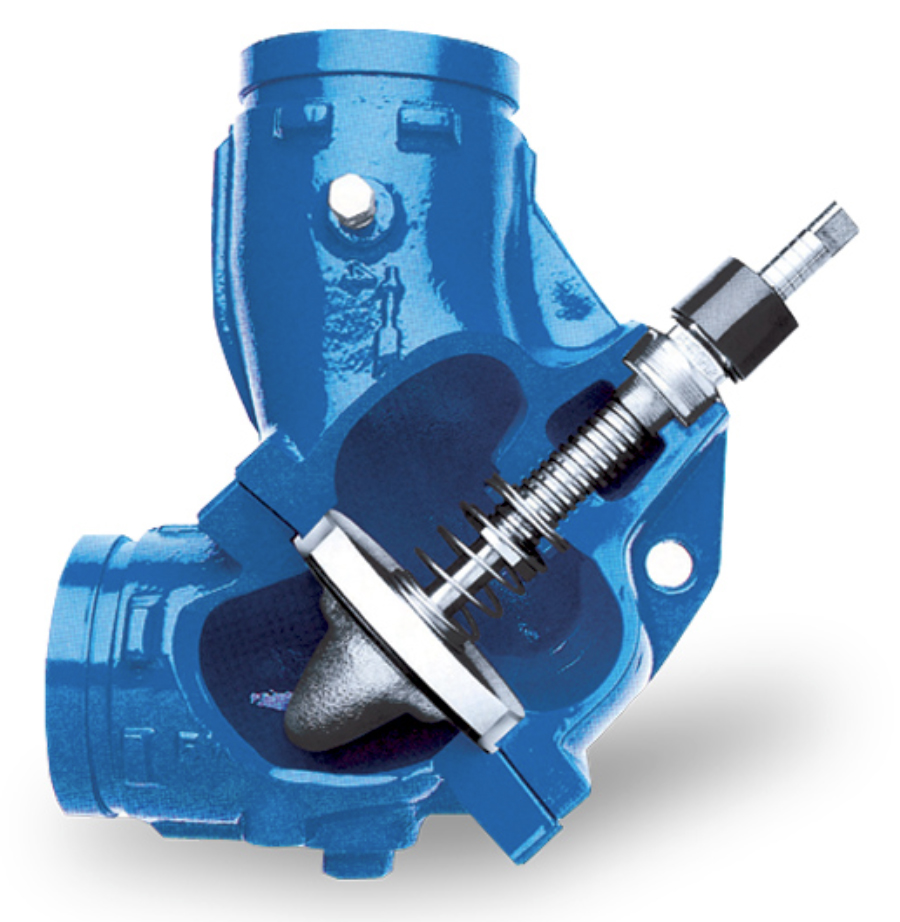

Pentair Auora 1040 Combination Valve

KEY FEATURES

- Combine check, throttling and shut-off valve reduces field installation and material costs

- Eliminates requirement for two separate valves on pump discharge and, in some cases, a 90° elbow

- 3DV-G eliminated three-welded flange connections

- Designed for installation on the discharge side of centrifugal pumps

- Drip-tight shut-off valve designed and tested for drip-tight isolation at 150% of working maximum pressure

- Flow throttling valve using a plug and disc design

- Non-slam check valve protecting it from slamming due to a reversal in flow caused by gravity or a recirculation from a parallel pump

- Convertible body design that permits the valve to be changed on site from straight to angle configuration

- 1-1/4″ NPT to 12″ Flanged

- Suitable for maximum working pressure up to 375 PSI and temperatures up to 300°F (150°C)

Expansion Tanks

Pentair Aurora 1060 Expansion Tanks

KEY FEATURES

- Manufactured in accordance with ASME Section VIII for unfired pressure vessels

- Available in 7 gallons to 211 gallons

- Steel tanks that can be horizontal or vertical

- Expansion tanks separate the air and water within the tank providing improved system performance

- Tanks can be up to 80% smaller than a conventional tank

- Reduced system corrosion and reduced requirement for chemical treatment

- Eliminates water-logged expansion tanks

- Stabilizes system pressure

- Dampens pressure transients (water hammer)

- Prevents air ingress

- Available in ASME or non-ASME models

Air Separators

Pentair Aurora 1050 Air Separator

KEY FEATURES

- Eliminate entrained air from heating and cooling systems

- Improve heat transfer efficiency in boilers, fan coils, chillers, etc.

- Reduces the overall energy costs of your system reduces service costs due to air-bound piping

- Allows quick venting of air at start-up

- Optimizes pump performance by reducing incidences of air lock

- Cast iron are available in 2″, 2.5″, 3″, 4″, 5″ and 6″ sizes

- Fabricated steel in 8″ to 24″ sizes

- Larger sizes also available

- 1″ to 24″ pipe inlet